The British Flame Research Committee Investigation of the Methane Destruction Efficiency of Flares

By Engaged Expert

Ali HussainWith a background in Aerospace Engineering, Ali specializes in aerodynamics and CFD studies for incinerator residence time/temperature.

Background

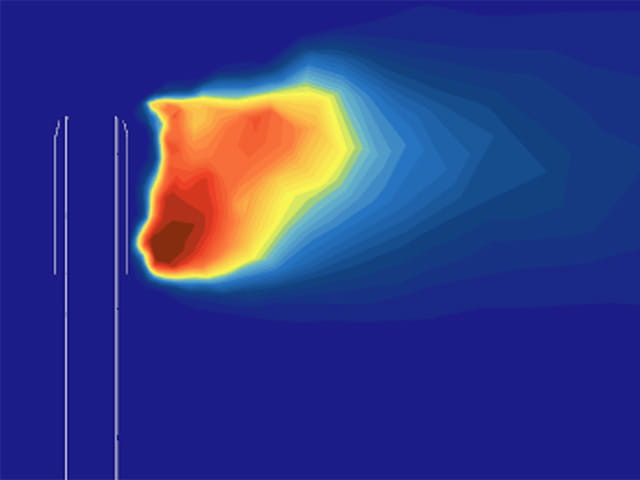

АФУХ2023ШЋФъе§АцУтЗбзЪСЯ Digital Engineering were approached by an Oil & Gas operator on behalf of the to conduct Computational Fluid Dynamics (CFD) simulations on a damaged flare tip. The aim was to carry out transient CFD simulations and determine the destruction efficiency of methane. This was done to inform the Oil & Gas industry about the reality of the destruction efficiency of flares in comparison to the industry-accepted values of 98-99% efficiency.

The Challenge

The challenge of this work was both to run transient CFD simulations of a damaged flare tip with multiple crosswind velocities and to accurately model the physics of combustion. This meant that the model needed to be optimized for capturing the region of the plume as well as capturing the combustion of methane. The crosswind needed to be modeled to interact with the flow of methane accurately as well. Following this, a calculation of all the methane destroyed in the fluid domain had to be carried out to determine the destruction efficiency of the flare tip.

The Solution

The solution showed that the destruction efficiency assumed by the Oil & Gas industry is far higher than what is actually predicted by CFD (around 18% higher). Parallel work using a different method came to a similar conclusion. This indicated that the Oil & Gas industry is operating with an unrealistic assumption for destruction efficiency which could be leading to greater environmental damage. More research work is needed to ensure the Oil & Gas industry is operating with accurate data regarding the destruction efficiency of their flares.

The Result

The result of this work has allowed for more research to take place in this field with validation methods being developed to ensure that CFD can be compared to experimental data. This will allow for better predictive capabilities for Oil & Gas clients who utilize АФУХ2023ШЋФъе§АцУтЗбзЪСЯ Digital Engineering’s CFD studies for their equipment.

If you would like to find out more about how we can help with your testing requirements, contact our experts today.

Find related Resources

Related Resources

Related Services

Digital Engineering Case Studies

Read examples of how АФУХ2023ШЋФъе§АцУтЗбзЪСЯ Digital Engineering utilize modeling, simulation, and other digital tools to help our customers innovate and solve complex challenges.

Modeling and Simulation Services

Optimize your project with our modeling and simulation services. Our expertise ensures cost-effective, compliant solutions. Enhance your project today.

Data Science and Machine Learning Services

We combine state-of-the-art data science and machine learning to provide insights that help you improve performance and increase productivity.

Join The Digital Engineering Team

АФУХ2023ШЋФъе§АцУтЗбзЪСЯ Digital Engineering is growing fast. We work at the forefront of АФУХ2023ШЋФъе§АцУтЗбзЪСЯ's digital transition, delivering insight, guidance and answers to complex engineering and technology challenges. Start your АФУХ2023ШЋФъе§АцУтЗбзЪСЯ journey today!